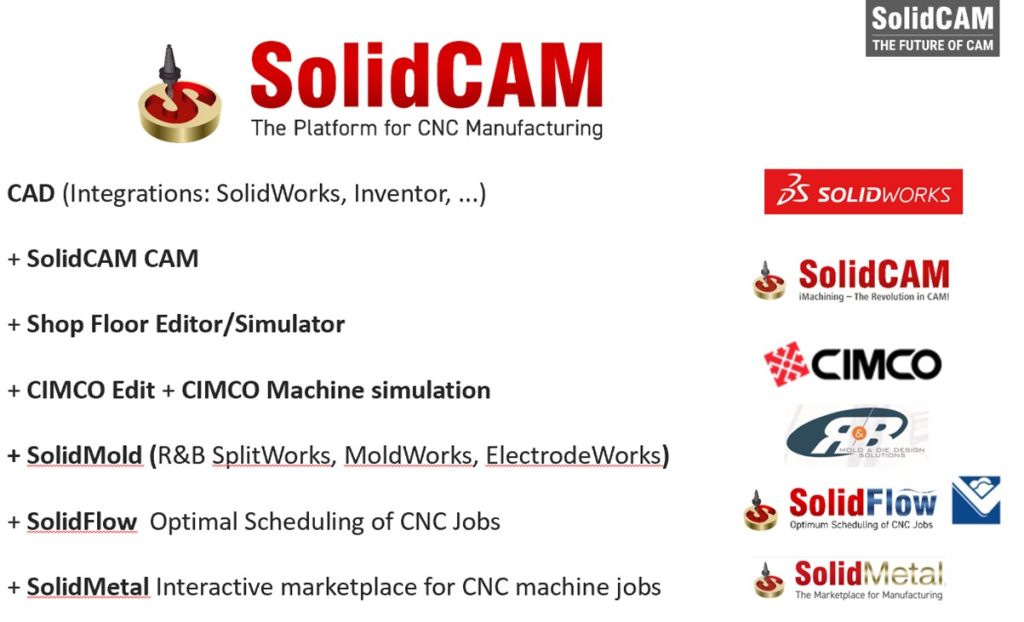

SolidCAM – The Complete Software Platform for CNC manufacturing

After having tens of thousands of CNC machine shops, engineering and manufacturing companies worldwide, using successfully our SolidCAM software for the CAM programming of all their CNC machines, including the most advanced ones, we decided to expand our software offerings to cover additional needs of our customers. Since our customers are so happy with our CAM software and our technical support, it is clear that they will be glad to get from us additional software products that complement their additional needs.

Many of our customers want to get more confidence and security, by having an additional external simulation of the G-code generated by the SolidCAM post processor, before sending it for execution at the CNC machine. So, we have OEMed a famous worldwide worldwide for GCode simulation, CIMCO, and we integrated it with our SolidCAM product, to be provided to all our customers.

Knowing that the CNC machine operators, would like to see the simulation of the CAM program and maybe do some small edits to it, before sending it to the CNC machine, we created the SolidCAM Shop Floor Editor & Simulator, to be used by the Operator besides the CNC machine, without having to interrupt the work of the SolidCAM CAM programmer to see the simulation.

In order to provide a complete CAD/CAM solution for Moldmakers, we have made an agreement with company R&B, to include their SolidWorks add-ins, SplitWorks, Moldworks and Electrodeworks, as part of our complete SolidWorks+SolidCAM solution. These add-ins provides great tools for the design of the Mold and the design of Electrodes.

Looking at the amount of CNC jobs that have to be manufactured in parallel at all our customers’ CNC machines, it was clear to us that they need the best software system for optimum scheduling, to be able to leverage all their CNC machines in the best way possible, to provide the final machined products on-time. We made an agreement with a US company, with 40 years experience in this field, and who have developed a unique scheduling method, called PFM (Protected Flow Manufacturing). PFM enables the CNC shop to drastically improve on-time delivery of CNC Jobs by prioritizing what needs to happen first, not what’s due first. This PFM technology will be offered as SolidFlow to all our customers.

Then we thought how we can further assist our CNC machine shop customers: obviously by providing them with an Interactive Marketplace on the Cloud, SolidMetal, where they can put data about all their CNCs and Services, then Buyers can post CNC jobs for them to execute. Only SolidCAM customers on Subscription and with iMachining2D/3D can use the services of SolidMetal. SolidCAM will make extensive marketing for the SolidMetal marketplace, so that Buyers worldwide can find it and post their CNC Jobs, asking for Quotes for them. SolidMetal is a unique service offered only by SolidCAM, and by no other CAM company.